Predictable Productivity Growth

Yield Revolution

The single biggest missed opportunity for cannabis companies is that they fail to continuously improve the yield of each cultivar they grow. Repeatability and scalability are the result of people, processes, genetics, and systems working together to create predictable productivity growth.

by Scott Campbell | President of AROYA

The US legal cannabis industry is growing at annual rates in excess of 30%. Most of this growth has been met by opening new cultivation and processing spaces. But below the surface, a quiet revolution is changing the future of this nascent market. The best cannabis companies are expanding their footprint and their yields. Getting more production out of the same asset base expands gross margins and protects producers from inevitable price swings.

The single biggest missed opportunity for cannabis companies is that they fail to continuously improve the yield of each cultivar they grow. Repeatability and scalability are the result of people, processes, genetics, and systems working together to create predictable productivity growth.

In this white paper, we will demystify the cannabis production process while identifying its biggest problems. We’ll then explore proven methods for addressing these challenges, and detail what CEOs should expect from operations leaders on their teams.

Traditional horticulture leaders like Windset Farms and Driscoll’s have proven that a relentless focus on efficiency is a sustainable competitive advantage. Most cannabis CEOs and CFOs are unprepared for how the yield revolution will change the competitive landscape over the next five years. With the right approach, continuously improving yields and quality is possible, but it will require a clear understanding of what success looks like -and a platform that allows your company to aggregate marginal gains across your entire operation.

Yield and the Future of Cannabis

Yields are the measuring stick for every cannabis operations team, but it’s hard to benchmark performance in an industry that’s shrouded in secrecy. Not so with corn. The yield (in bushels/acre) is a matter of public record stretching back to 1866, and the trend is impressive:

Corn yields have increased by more than 7X since 1937 due to improved varieties, the advent of mechanized farming, and the widespread adoption of industrial fertilizer and pesticides. As cannabis cultivation and research emerges from the shadows, yields are sure to increase - and will do so much faster than in corn production for 2 critical reasons (more on that later). That means cannabis producers who don’t participate in the coming yield revolution risk falling behind competitors in this fast-paced industry.

For an indoor grower, the best productivity metric is grams per square foot per year (g/ft2/yr) for determining how well you grow and process plants, and the number of harvests you can get in one year. Grams are defined as dried, cured, trimmed flower ready to package for sale. Here are some industry productivity benchmarks:

- Outdoor - 3-10g/sqft

- Greenhouse (no supplemental light) - 8-25g/sqft

- Greenhouse (supplemental light) - 20-60 g/sqft

- Indoor - 40-120 g/sqft

Become Plant-Literate in 3 Minutes

Don’t panic - even high-powered executives can benefit from knowing some cultivation basics. Cannabis plants are resilient, drought tolerant, and grow like, well, weeds. This creates a false sense of security though, because while almost anyone can grow cannabis plants, few know how to do it well.

Let’s say your team starts a new crop of Blue Dream plants. What will determine whether you get lots of top shelf product from your harvest? Two things: the atmosphere and the rhizosphere. The atmosphere consists of temperature, humidity, light, and CO2. The rhizosphere is where plant roots live and its variables are water content, electrical conductivity (from fertilizer), oxygen, and root temperature.

Like humans, the best environment for cannabis plants depends on their maturity. Cannabis plants have 5 major growth phases. Here is a table showing the general guidelines:

Don’t worry, there won’t be a quiz. The point is that growers must choose the conditions that are right for each phase of growth. Without a way to measure and record atmosphere and rhizosphere data, they will be flying blind.

There are four levels of grower competency:

- Can’t create a clean, consistent environment for plants

- Can create a clean, consistent environment for plants

- Can match environment to cannabis plant phases generally

- Can select and execute the best environment for each individual cultivar

A tall, lanky plant like Blue Dream loves to be stressed, which will result in better quality and yield. It takes the best growers to not only select the right strategy cannabis plants in general, but to also match conditions to your Blue Dream plants.

Production is More Than Cultivation

The previous section was about growing plants, but turning harvested plants into saleable flower takes much more than a talented grower. Cannabis production consists of three main steps:

- Planning: Selecting and sourcing the genetics for the plants you want to grow

- Cultivation: Growing the plants to maturity

- Post-Harvest Processing: Processing the salable parts of the cannabis plant into final form

Planning and post-harvest processing can determine whether cultivation efforts result in revenue and profit. It is important to recognize that your company’s profitability depends on successful cannabis production - not just cultivation.

The Four Forces of Cannabis Production

Cannabis production relies on four key components - people, processes, genetics, and systems - each of which must be managed properly to achieve even a baseline performance. Let’s define them in more detail:

People: This includes positions like VP-Cultivation, Master Grower, Director of Cultivation, Grow Techs, Maintenance, Trim Crew, Harvest Team, Compliance Manager, Director of Operations, Processing Manager. The quality of your production team is the single most important factor in determining your operational efficiency. This is because your people exist to solve problems in the other key areas of processes, systems, and genetics.

Processes: Processes include all of your SOPs, tasks, production scheduling, best practices, and recipes. Standardization of processes helps create consistency, scalability, and repeatability in operations.

Genetics: This is the variety of cultivars that you grow, maintain, and process at your facilities. Genetics can come from many sources including commercial nurseries, pheno-hunting, or cultivars you’ve grown for years.

Systems: These are the physical and digital systems that allow your company to produce cannabis: buildings, HVAC, irrigation/fertigation, ERP, sensor, compliance, seed-to-sale, and analytics platforms. The two most common “systems” cannabis companies use to manage their business are a whiteboard and Google Sheets.

The Bad News

If you’re not careful, these four forces can create a vicious cycle that undermines the productivity of your operations. For example, it’s not uncommon for cannabis producers to have high staff turnover, even among lead growers. When this happens you lose tribal knowledge, and are forced to spend time onboarding new team members instead of improving operational efficiency.

In addition to staff turnover, producers are pressured to launch new cultivars to meet changing consumer demands. Each new cultivar brings differences in potency, morphology, disease resistance, salt-tolerance, vigor, and phase duration. Achieving peak productivity with a new cultivar takes time, and each cultivar you sunset means saying goodbye to proven cultivation methods.

Most established agricultural industries have processes and systems in place to address challenges with staff or genetics. Cannabis, however, lacks both the purpose-built systems and depth of academic research that are common to, say, viticulture. Indoor growers must contend with an unholy marriage of HVAC, irrigation, and lighting systems that were made for other industries. None of these systems communicate with each other, nor do they sync their data to cultivar batch records or meet government track/trace requirements.

The Good News

Cheer up! As dispiriting as it is to have the four forces work against you, when managed correctly they can become powerful success drivers. What’s more, the cannabis industry is primed for explosive yield growth for two reasons:

- Velocity - Each cultivar and each harvest is an opportunity to learn. Multiply the number of cultivars you grow by the number of harvests in a year, and that’s how many times you can improve in a year. For a corn farmer, that number is probably 2. For a cannabis producer that grows 12 cultivars, that number is 70.

- Technology - Modern digital platforms make it possible to collect input and outcome data for all cultivar runs across your operations. Such systems are called “cannabis production platforms”.

The path to growth is difficult but simple. It requires a cannabis production platform that connects your people, your plant genetics, and your processes to continuously improve g/ft2/year.

Recall that cannabis production consists of planning, cultivation, and post-harvest processing. By taking the added steps of carefully analyzing outcomes and changing your controllable input metrics for the next harvest, your production efforts can look like this:

A cannabis production platform must therefore include:

- Inputs - accurate sources of data from the rhizosphere and atmosphere

- Outcomes - quality and yield in terms of salable dried cured flower or derivatives

- Cultivar Runs - a unique identifier for each batch of plants that were grown together, including inputs and outcomes

- Workflow Tools - dashboards, alerts, tasks, etc. that improve operational efficiency

- Recipes - customizable plans for how a grower wants to grow each cultivar

- The Whole Process - coverage for both cultivation and post-harvest processing

As a CEO, CFO, or COO, here are four questions that can anchor the operations discussion at each QBR:

- What is our 3-month, 6-month, and 1 year g/sqft/year by facility?

- What is our 3-month, 6-month, and 1 year g/sqft/year by cultivar?

- How fast are new cultivars reaching peak productivity?

- What is the single biggest impediment to improving g/sqft/year?

Low-Hanging Flower

Now that you’ve seen how the yield revolution is happening, we’re ready to get even more detailed. The two biggest mistakes that keep yields low are simple and addressable:

- Insufficient amounts of light and water stress during cultivation

- Overdrying in dry/cure/trim

By implementing a production platform that solves these two problems, cannabis producers can raise yields by between 3 and 15 grams/square foot. Here’s what that looks like in the real world.

Aurora Cannabis is the 4th largest Canadian producer of cannabis, and is an excellent example of how yield affects financials. The following are from its 2021 financial reports:

- Annual Revenue: $240M CAD

- Production Square Footage: 472,000

- Cannabis Production: 64,500 kilograms

From these, we can calculate the following:

- Blended Price Per Gram: $3.24 USD

- Blended Cost Per Gram: $1.63 USD USD

- Blended Packaging Cost/gram: $0.16 USD

- Blended Processing Cost/gram: $0.51 USD

- Blended Cultivation Cost/gram: $0.96 USD

Assuming that 40% of COGS comes from packaging and post-harvest processing, increased yield will have the following effect on Aurora’s profit:

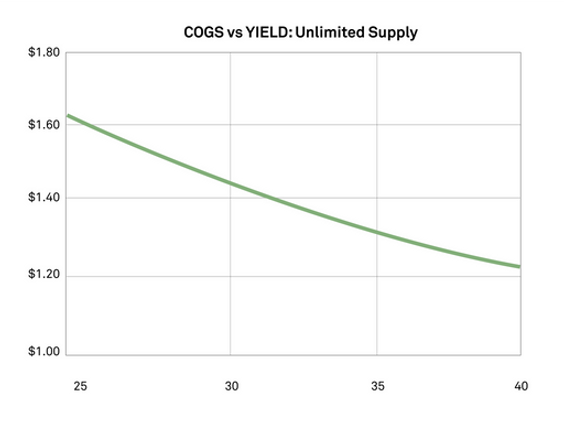

Maybe you’re a skeptic who believes that Canada’s legal market can’t absorb any more supply. Here’s how yield increases will affect COGS, which will increase profits even if Aurora can’t sell another gram of product:

Although the effect isn’t as powerful, increasing yield to 40g/sqft would have resulted in another $24M in profit during fiscal 2021.

Yield First

But an important question still remains: should you target input cost reduction before yield increases? This will depend on the price of each incremental improvement in cost or yield. As noted above, this also depends on whether additional yield can be sold at market prices. Since AROYA is a cannabis production platform, we know the cost for a company with 472,000 square feet of growing space. Assuming Aurora achieves a 2.5 gram improvement in yield after incurring a $140k system cost for each gram, within 1 year the return will be an $800k increase in profit for a demand-constrained market, and a $3.3M increase in profit in a market with unlimited demand.

Let’s compare that to input costs for making cannabis, which can be seen in the following table:

While careful buying is always a must, opportunities to save on commodities are rare. The same can be said for fixed costs like rent and state/local taxes. That makes manual labor the largest input cost for cannabis producers.

Here’s how increasing yield compares with reducing labor costs:

For the purposes of this comparison, we have assumed that labor-saving robotics are available for purchase. However, the legal cannabis industry is so new that automation robotics for tasks like plant pruning and trimming is in its infancy. Although those technologies will eventually drive cost reduction, they are not fit for purpose at the time of this writing.

This doesn’t mean you should ignore labor costs. In fact, a cannabis production platform can play a key role in reducing labor costs if it has the following capabilities:

- Task management

- Labor tracking

- Automation of manual data collection

- Touchless harvest (RFID-enabled harvest weights)

- Integrated Pest Management and documentation

These features will allow you to build the foundation for future cost-reduction efforts, but the takeaway is clear: investing to increase yield will result in profit growth that is 10-20 times faster than a program to reduce labor costs.

Roll Your Own?

The platform described above is rare in cannabis, and not covered by legacy systems. Here is a comparison of critical system elements and tools you may already have:

Though they may be new to you, production platforms are common in traditional horticulture sectors like tomatoes, cucumbers, and strawberries. Windset Farms, which grows greenhouse produce on 11M square feet, uses a home-built production platform to achieve continuous improvement. Similarly, berry producer Driscoll’s has built and deployed a proprietary data platform across its vast network of growers.

As you may guess, building and operating a cannabis production platform takes substantial resources. In future white papers, we’ll show you some of the exciting things AROYA has done to create the ultimate cannabis production platform.

About AROYA

AROYA is a division of ADDIUM Inc., a company that has been serving agricultural production and research since 1982. Founded by soil scientist Gaylon Campbell, Ph.D., ADDIUM Inc. is headquartered near Washington State University in Pullman, WA. AROYA was launched in 2019 to bring applied science to cannabis production.

Ready to Book a demo? Our Client Success Team is ready to walk you through all the ways AROYA can work for you!

Emerging Markets Roundup: January 2023

January 2023 Roundup

Learn about new emerging market news in the cannabis industry for January 2023 from AROYA.

When to cultivate cannabis

Education Guides

Learn about the key indicators that let you know your cannabis plants are ready.